The choice of a ventilation system primarily depends on the climate in your region and how you arrange the bags or briquettes with the substrate.

The oyster mushroom growing system (whether it includes an incubation room or not) also plays a significant role.

To some extent, the choice of ventilation system may also be influenced by the substrate composition. I will describe these details in this article.

Table of Contents:

The amount of fresh air required depends directly on the number of growing mushrooms in the grow room.

Many mushroom growers misunderstand why outside air is necessary. Oyster mushrooms have sufficient oxygen for respiration.

Fresh air is primarily needed to replace the air inside the grow room and remove excess carbon dioxide.

This is why it’s not just about the quantity of air but about ensuring proper air exchange at a specific flow rate. The airflow carries CO₂ away from the growing oyster mushroom clusters. This flow must be constant, meaning the ventilation system should run 24/7.

📌 Related articles:

- about CO2 levels

- about air exchange

Passive-active ventilation is a system where air passively enters the grow room while an exhaust fan actively removes it.

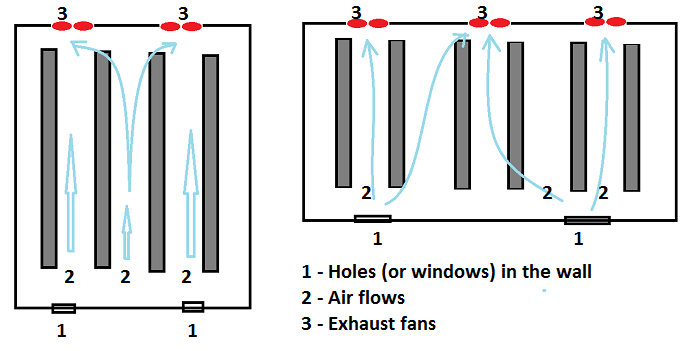

💡 Important: Exhaust fans must be placed on the wall opposite the air intake holes, as shown in this diagram. Air should flow along the mushroom rows.

The room height must be at least 3 meters (10 feet).

This system is called Tornado—axial fans are installed under the ceiling to accelerate and mix airflow, efficiently removing CO₂.

One or more axial fans are placed below to provide exhaust.

During warm seasons, evaporative panels are placed in air intake holes to cool and humidify the air.

The distance between the air intake holes and the exhaust fans should not exceed 8–10 meters (26–33 feet), or the airflow speed will drop significantly.

This can lead to uneven mushroom growth, causing some to have undesirable shapes.

Solution:

✅Install additional axial fans under the ceiling in key areas to improve air distribution.

✅ Additional Exhaust Fans

- If your mushroom blocks are stacked 3 meters (10 feet) or higher and your room layout resembles the left diagram↑, consider installing four smaller exhaust fans instead of two.

Fan placement:

- Install two fans on top of each other at each position marked (3) on the diagram.

- If your grow room layout resembles the right diagram, you need six fans

or👇

- Place one fan in the center at 1.5 meters (5 feet) above the floor.

- Install two fans on each side—one at a height of 70–80 cm (2.3–2.6 feet) above the floor and another at 2–2.1 meters (6.6–7 feet) above the floor.

Solutions:

✅ Option 1: Heating & Humidification Units

- Place heating and humidification units near the intake holes. However, this may reduce airflow speed, so additional fans may be needed to compensate.

✅ Option 2: Corridor System for Pre-Treated Air

- Construct a long corridor near the air intake wall.

- Install a large opening in the corridor with a heat exchanger near it.

- Further down the corridor, place a humidifier.

- From this corridor, heated and humidified air flows into the grow room through the air intake wall.

Using a blower fan to actively supply fresh air into an oyster mushroom grow room is a much more common approach.

Air removal can be either:

✅ Active – using exhaust fans.

✅ Passive – using gravity shutters.

A similar active-passive ventilation method is also used in button mushroom production.

📌 Read more about this type of ventilation in my article.

This is the most versatile ventilation system. You can:

• Buy a pre-assembled unit that includes heating and humidification, designed for a specific number of substrate tons.

• Build your own system using a blower fan, heat exchanger, and humidifier.

Additionally, automated climate control systems for mushroom grow rooms have been developed specifically for this type of ventilation.

💡Many temperature and humidity controllers used in poultry incubators can also be adapted for oyster mushroom cultivation.

In some cases, fresh air alone is not enough, and you need a system that recirculates air from the grow room (also known as air recirculation or air mixing, depending on the region).

In this setup, recirculation is necessary regardless of climate conditions.

📌 Learn more about the single-zone system here.

Here’s how it works:

If the block center temperature rises above 33°C (91°F):

Use a cooler or air conditioning system while keeping ventilation in recirculation mode.

As the mycelium develops, gradually introduce fresh air, adjusting CO₂ levels according to the incubation schedule.

Fresh air requirements during fruiting:

If your region experiences:

Then a recirculation system is required for any oyster mushroom growing setup—whether you use an incubation room or not.

Why?

💡 Oyster mushrooms can tolerate less-than-ideal temperature and humidity conditions, but they do not handle sudden changes well. Keeping a stable environment ensures consistent growth and yield.

Choosing the right ventilation system for oyster mushroom cultivation depends on several factors:

✅ Climate conditions in your region.

✅ Growing method (with or without an incubation room).

✅ Substrate arrangement (stacks, shelves, or blocks on the floor).

1️⃣ Passive-active ventilation – uses exhaust fans to pull air out, allowing fresh air to enter naturally. Suitable for warm climates and simple grow setups.

2️⃣ Active ventilation – forces fresh air in using a blower fan, often combined with heating, humidification, and recirculation for better climate control.

🔄 Recirculation is necessary if:

- You use a single-zone growing system (without a separate incubation room).

- Your climate has large temperature fluctuations or extreme seasonal conditions.

💡 Stable airflow is more important than just the amount of air. Maintaining consistent CO₂ levels and temperature helps prevent growth issues and maximizes yield.

📌 Check my other articles for more details on CO₂ levels, air exchange, and climate control in grow rooms.